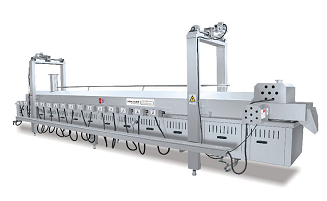

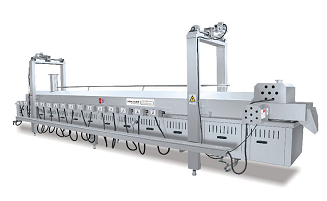

Product alias: automatic continuous frying line Brand: CH Model: CH6000 Voltage: 380V (V) Power: 120KW (kw) Product use: food frying Dimensions: 6000*1200*1600mm (mm) Net weight: 600kg (kg)

PRODUCT PARAMETER

This machine uses double mesh belts to transport food, and the upper and lower mesh belts can be frequency-converted. The user can adjust the transmission speed of the mesh belt according to the different fried foods. Equipped with a high-efficiency burner, the temperature rises quickly and the production efficiency is high. An electric lifting system is provided to facilitate workers to clean and maintain the machine body. In addition, there is an automatic smoke exhaust system and a constant temperature continuous production system to ensure that workers have a good working environment to avoid smoke and fire, while ensuring that the frying temperature of the food is consistent, so that the fried food tastes more crispy.

The whole machine is made of stainless steel, strong and durable, equipped with a burner to raise the temperature quickly, and the production efficiency is high. The entire mesh belt can be lifted to make the mesh belt leave the oil surface, which is convenient for the maintenance of the frying line, frying time, frying temperature, Automatic control of water temperature cooling, deoiling, etc. It is realized that there are no carbonized substances in the oil, the oil will not turn black, the use cycle is long, the fried food has bright color and good taste.

【Equipment structure】

Basic structure: oil temperature automatic control system, automatic lifting system, automatic filtering and scraping system

Heating system: electric heating pipe, heat transfer oil, coal, natural gas, liquefied gas

Mesh belt conveying system: frequency conversion speed regulation, quantitative and timing conveying

Automatic filtration system: dynamic circulation system

【Features】

1. The automatic slag scraping system collects the residues in the production process and discharges them out of the equipment.

2. The mechanical configuration and control can maintain a good working condition, not only increase the output, but also make the product quality stable, and the color, fragrance and taste are unified.

3. The automatic filtering of this machine can prolong the service life of frying oil without frequent oil change. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel saving efficiency is improved.

4. The efficient heating system avoids energy waste and saves energy expenditure

5. The realization of continuous work of this machine improves the work efficiency of the unit, effectively reduces the unit cost, and is also helpful for labor expenditure and management expenditure.

6. The use of this equipment can greatly improve product quality, reduce various costs in the production process, and make your products competitive in the market.

Suitable for frying a variety of foods: broad beans, peanut beans, green beans and other nuts; rice crackers, French fries, potato chips and other puffed products; rice noodles, cat ears, shaqima, twists and other noodles; diced meat, meatloaf, Meat products such as chicken thighs; aquatic products such as yellow croaker and hairtail; soy products such as dried tofu and tofu foam.

PRODUCT PARAMETER

This machine uses double mesh belts to transport food, and the upper and lower mesh belts can be frequency-converted. The user can adjust the transmission speed of the mesh belt according to the different fried foods. Equipped with a high-efficiency burner, the temperature rises quickly and the production efficiency is high. An electric lifting system is provided to facilitate workers to clean and maintain the machine body. In addition, there is an automatic smoke exhaust system and a constant temperature continuous production system to ensure that workers have a good working environment to avoid smoke and fire, while ensuring that the frying temperature of the food is consistent, so that the fried food tastes more crispy.

The whole machine is made of stainless steel, strong and durable, equipped with a burner to raise the temperature quickly, and the production efficiency is high. The entire mesh belt can be lifted to make the mesh belt leave the oil surface, which is convenient for the maintenance of the frying line, frying time, frying temperature, Automatic control of water temperature cooling, deoiling, etc. It is realized that there are no carbonized substances in the oil, the oil will not turn black, the use cycle is long, the fried food has bright color and good taste.

【Equipment structure】

Basic structure: oil temperature automatic control system, automatic lifting system, automatic filtering and scraping system

Heating system: electric heating pipe, heat transfer oil, coal, natural gas, liquefied gas

Mesh belt conveying system: frequency conversion speed regulation, quantitative and timing conveying

Automatic filtration system: dynamic circulation system

【Features】

1. The automatic slag scraping system collects the residues in the production process and discharges them out of the equipment.

2. The mechanical configuration and control can maintain a good working condition, not only increase the output, but also make the product quality stable, and the color, fragrance and taste are unified.

3. The automatic filtering of this machine can prolong the service life of frying oil without frequent oil change. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel saving efficiency is improved.

4. The efficient heating system avoids energy waste and saves energy expenditure

5. The realization of continuous work of this machine improves the work efficiency of the unit, effectively reduces the unit cost, and is also helpful for labor expenditure and management expenditure.

6. The use of this equipment can greatly improve product quality, reduce various costs in the production process, and make your products competitive in the market.

Suitable for frying a variety of foods: broad beans, peanut beans, green beans and other nuts; rice crackers, French fries, potato chips and other puffed products; rice noodles, cat ears, shaqima, twists and other noodles; diced meat, meatloaf, Meat products such as chicken thighs; aquatic products such as yellow croaker and hairtail; soy products such as dried tofu and tofu foam.

PRODUCT PARAMETER

This machine uses double mesh belts to transport food, and the upper and lower mesh belts can be frequency-converted. The user can adjust the transmission speed of the mesh belt according to the different fried foods. Equipped with a high-efficiency burner, the temperature rises quickly and the production efficiency is high. An electric lifting system is provided to facilitate workers to clean and maintain the machine body. In addition, there is an automatic smoke exhaust system and a constant temperature continuous production system to ensure that workers have a good working environment to avoid smoke and fire, while ensuring that the frying temperature of the food is consistent, so that the fried food tastes more crispy.

The whole machine is made of stainless steel, strong and durable, equipped with a burner to raise the temperature quickly, and the production efficiency is high. The entire mesh belt can be lifted to make the mesh belt leave the oil surface, which is convenient for the maintenance of the frying line, frying time, frying temperature, Automatic control of water temperature cooling, deoiling, etc. It is realized that there are no carbonized substances in the oil, the oil will not turn black, the use cycle is long, the fried food has bright color and good taste.

【Equipment structure】

Basic structure: oil temperature automatic control system, automatic lifting system, automatic filtering and scraping system

Heating system: electric heating pipe, heat transfer oil, coal, natural gas, liquefied gas

Mesh belt conveying system: frequency conversion speed regulation, quantitative and timing conveying

Automatic filtration system: dynamic circulation system

【Features】

1. The automatic slag scraping system collects the residues in the production process and discharges them out of the equipment.

2. The mechanical configuration and control can maintain a good working condition, not only increase the output, but also make the product quality stable, and the color, fragrance and taste are unified.

3. The automatic filtering of this machine can prolong the service life of frying oil without frequent oil change. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel saving efficiency is improved.

4. The efficient heating system avoids energy waste and saves energy expenditure

5. The realization of continuous work of this machine improves the work efficiency of the unit, effectively reduces the unit cost, and is also helpful for labor expenditure and management expenditure.

6. The use of this equipment can greatly improve product quality, reduce various costs in the production process, and make your products competitive in the market.

Suitable for frying a variety of foods: broad beans, peanut beans, green beans and other nuts; rice crackers, French fries, potato chips and other puffed products; rice noodles, cat ears, shaqima, twists and other noodles; diced meat, meatloaf, Meat products such as chicken thighs; aquatic products such as yellow croaker and hairtail; soy products such as dried tofu and tofu foam.

PRODUCT PARAMETER

This machine uses double mesh belts to transport food, and the upper and lower mesh belts can be frequency-converted. The user can adjust the transmission speed of the mesh belt according to the different fried foods. Equipped with a high-efficiency burner, the temperature rises quickly and the production efficiency is high. An electric lifting system is provided to facilitate workers to clean and maintain the machine body. In addition, there is an automatic smoke exhaust system and a constant temperature continuous production system to ensure that workers have a good working environment to avoid smoke and fire, while ensuring that the frying temperature of the food is consistent, so that the fried food tastes more crispy.

The whole machine is made of stainless steel, strong and durable, equipped with a burner to raise the temperature quickly, and the production efficiency is high. The entire mesh belt can be lifted to make the mesh belt leave the oil surface, which is convenient for the maintenance of the frying line, frying time, frying temperature, Automatic control of water temperature cooling, deoiling, etc. It is realized that there are no carbonized substances in the oil, the oil will not turn black, the use cycle is long, the fried food has bright color and good taste.

【Equipment structure】

Basic structure: oil temperature automatic control system, automatic lifting system, automatic filtering and scraping system

Heating system: electric heating pipe, heat transfer oil, coal, natural gas, liquefied gas

Mesh belt conveying system: frequency conversion speed regulation, quantitative and timing conveying

Automatic filtration system: dynamic circulation system

【Features】

1. The automatic slag scraping system collects the residues in the production process and discharges them out of the equipment.

2. The mechanical configuration and control can maintain a good working condition, not only increase the output, but also make the product quality stable, and the color, fragrance and taste are unified.

3. The automatic filtering of this machine can prolong the service life of frying oil without frequent oil change. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel saving efficiency is improved.

4. The efficient heating system avoids energy waste and saves energy expenditure

5. The realization of continuous work of this machine improves the work efficiency of the unit, effectively reduces the unit cost, and is also helpful for labor expenditure and management expenditure.

6. The use of this equipment can greatly improve product quality, reduce various costs in the production process, and make your products competitive in the market.

Suitable for frying a variety of foods: broad beans, peanut beans, green beans and other nuts; rice crackers, French fries, potato chips and other puffed products; rice noodles, cat ears, shaqima, twists and other noodles; diced meat, meatloaf, Meat products such as chicken thighs; aquatic products such as yellow croaker and hairtail; soy products such as dried tofu and tofu foam.

PRODUCT PARAMETER

This machine uses double mesh belts to transport food, and the upper and lower mesh belts can be frequency-converted. The user can adjust the transmission speed of the mesh belt according to the different fried foods. Equipped with a high-efficiency burner, the temperature rises quickly and the production efficiency is high. An electric lifting system is provided to facilitate workers to clean and maintain the machine body. In addition, there is an automatic smoke exhaust system and a constant temperature continuous production system to ensure that workers have a good working environment to avoid smoke and fire, while ensuring that the frying temperature of the food is consistent, so that the fried food tastes more crispy.

The whole machine is made of stainless steel, strong and durable, equipped with a burner to raise the temperature quickly, and the production efficiency is high. The entire mesh belt can be lifted to make the mesh belt leave the oil surface, which is convenient for the maintenance of the frying line, frying time, frying temperature, Automatic control of water temperature cooling, deoiling, etc. It is realized that there are no carbonized substances in the oil, the oil will not turn black, the use cycle is long, the fried food has bright color and good taste.

【Equipment structure】

Basic structure: oil temperature automatic control system, automatic lifting system, automatic filtering and scraping system

Heating system: electric heating pipe, heat transfer oil, coal, natural gas, liquefied gas

Mesh belt conveying system: frequency conversion speed regulation, quantitative and timing conveying

Automatic filtration system: dynamic circulation system

【Features】

1. The automatic slag scraping system collects the residues in the production process and discharges them out of the equipment.

2. The mechanical configuration and control can maintain a good working condition, not only increase the output, but also make the product quality stable, and the color, fragrance and taste are unified.

3. The automatic filtering of this machine can prolong the service life of frying oil without frequent oil change. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel saving efficiency is improved.

4. The efficient heating system avoids energy waste and saves energy expenditure

5. The realization of continuous work of this machine improves the work efficiency of the unit, effectively reduces the unit cost, and is also helpful for labor expenditure and management expenditure.

6. The use of this equipment can greatly improve product quality, reduce various costs in the production process, and make your products competitive in the market.

Suitable for frying a variety of foods: broad beans, peanut beans, green beans and other nuts; rice crackers, French fries, potato chips and other puffed products; rice noodles, cat ears, shaqima, twists and other noodles; diced meat, meatloaf, Meat products such as chicken thighs; aquatic products such as yellow croaker and hairtail; soy products such as dried tofu and tofu foam.

PRODUCT PARAMETER

This machine uses double mesh belts to transport food, and the upper and lower mesh belts can be frequency-converted. The user can adjust the transmission speed of the mesh belt according to the different fried foods. Equipped with a high-efficiency burner, the temperature rises quickly and the production efficiency is high. An electric lifting system is provided to facilitate workers to clean and maintain the machine body. In addition, there is an automatic smoke exhaust system and a constant temperature continuous production system to ensure that workers have a good working environment to avoid smoke and fire, while ensuring that the frying temperature of the food is consistent, so that the fried food tastes more crispy.

The whole machine is made of stainless steel, strong and durable, equipped with a burner to raise the temperature quickly, and the production efficiency is high. The entire mesh belt can be lifted to make the mesh belt leave the oil surface, which is convenient for the maintenance of the frying line, frying time, frying temperature, Automatic control of water temperature cooling, deoiling, etc. It is realized that there are no carbonized substances in the oil, the oil will not turn black, the use cycle is long, the fried food has bright color and good taste.

【Equipment structure】

Basic structure: oil temperature automatic control system, automatic lifting system, automatic filtering and scraping system

Heating system: electric heating pipe, heat transfer oil, coal, natural gas, liquefied gas

Mesh belt conveying system: frequency conversion speed regulation, quantitative and timing conveying

Automatic filtration system: dynamic circulation system

【Features】

1. The automatic slag scraping system collects the residues in the production process and discharges them out of the equipment.

2. The mechanical configuration and control can maintain a good working condition, not only increase the output, but also make the product quality stable, and the color, fragrance and taste are unified.

3. The automatic filtering of this machine can prolong the service life of frying oil without frequent oil change. The oil consumed during the frying process of the product is equivalent to the oil absorbed by the product, and the fuel saving efficiency is improved.

4. The efficient heating system avoids energy waste and saves energy expenditure

5. The realization of continuous work of this machine improves the work efficiency of the unit, effectively reduces the unit cost, and is also helpful for labor expenditure and management expenditure.

6. The use of this equipment can greatly improve product quality, reduce various costs in the production process, and make your products competitive in the market.

Suitable for frying a variety of foods: broad beans, peanut beans, green beans and other nuts; rice crackers, French fries, potato chips and other puffed products; rice noodles, cat ears, shaqima, twists and other noodles; diced meat, meatloaf, Meat products such as chicken thighs; aquatic products such as yellow croaker and hairtail; soy products such as dried tofu and tofu foam.