Condition: New Place of Origin: Shandong China Brand Name: CH Machinery Model Number : CH-65,CH-70,CH-85,CH-90,CH-95,CH-120,CH-130 Output: 100-150kg/hour,200-240kg/h,300-400kg/h, 500-600kg/h, 1-1.2t/h, 2-2.5t/h. Voltage: Make based on customers’ factory voltage Dimension(L*W*H):based on production capacity Certification: CE, ISO9001 Warranty: 1year After-sales Service Provided: Field installation, commissioning and training Layout: Auto CAD format according to client's workshop

Fish feed extruder

Puffing technology refers to a certain moisture content of material is fed into extrusion machine, under the impetus of the screw, screw, material forming axial moving forward, material and screw, material to the mechanical friction within the barrel and material, the material being strong extrusion mixing, shearing, is further refined materials, homogenization, then machine the inside of the cavity pressure and temperature increasing and increases, Under the action of high temperature, high pressure and high shear force, the material components undergo complex physical and chemical changes. After the paste material is ejected from the die hole, the pressure difference is generated instantaneously, and the material is expanded, thus forming the expanded product with loose structure, porous and crisp. Twin-screw extruder fish feed production machinery aquatic feed production line quality is excellent

After puffing treatment, feed raw materials have a unique fragrance and fluffy feeling, good palatability, high gelatinization degree, and a good role in inducing food. At the same time, the long-chain structure of some organic matter such as protein and fat becomes short-chain structure, which makes it easier for animals to digest and absorb. The extruded feed grain size is small, crisp, and released char flavor, palatability is improved. The EXPANDED FEED BECOMES loose and disordered structure, and this change provides a larger contact area for enzymes, which is conducive to the contact of starch chain, peptide chain and digestive enzymes, and is conducive to the digestion and absorption of feed, so as to improve the digestibility of feed.

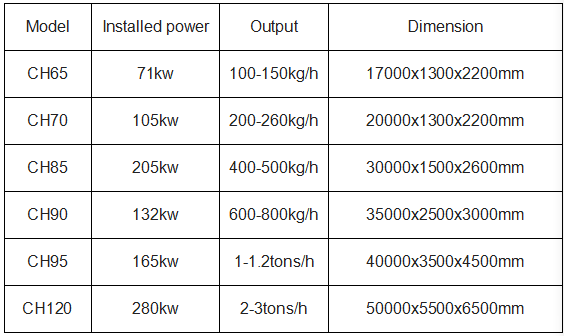

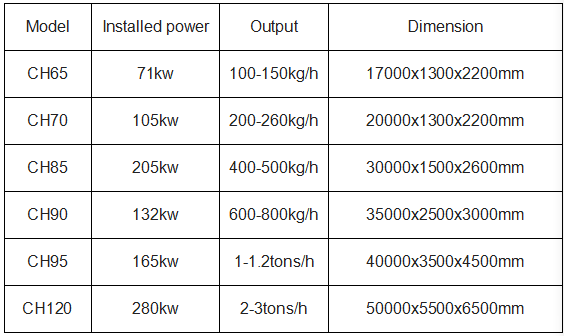

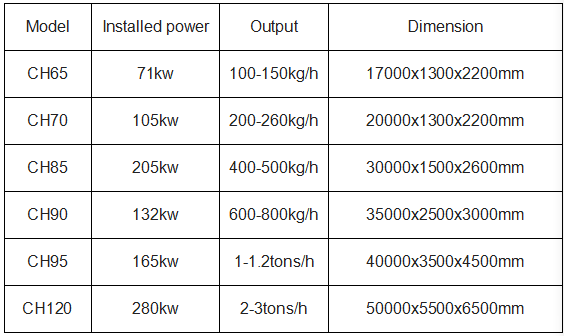

Product parameter

Select the model based on the production capacity.

Double screw extruder applications

Double screw extruders can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, turtle, bullfrog and other aquarium feed particles. Also can also make dog food

Fish feed extruder

Puffing technology refers to a certain moisture content of material is fed into extrusion machine, under the impetus of the screw, screw, material forming axial moving forward, material and screw, material to the mechanical friction within the barrel and material, the material being strong extrusion mixing, shearing, is further refined materials, homogenization, then machine the inside of the cavity pressure and temperature increasing and increases, Under the action of high temperature, high pressure and high shear force, the material components undergo complex physical and chemical changes. After the paste material is ejected from the die hole, the pressure difference is generated instantaneously, and the material is expanded, thus forming the expanded product with loose structure, porous and crisp. Twin-screw extruder fish feed production machinery aquatic feed production line quality is excellent

After puffing treatment, feed raw materials have a unique fragrance and fluffy feeling, good palatability, high gelatinization degree, and a good role in inducing food. At the same time, the long-chain structure of some organic matter such as protein and fat becomes short-chain structure, which makes it easier for animals to digest and absorb. The extruded feed grain size is small, crisp, and released char flavor, palatability is improved. The EXPANDED FEED BECOMES loose and disordered structure, and this change provides a larger contact area for enzymes, which is conducive to the contact of starch chain, peptide chain and digestive enzymes, and is conducive to the digestion and absorption of feed, so as to improve the digestibility of feed.

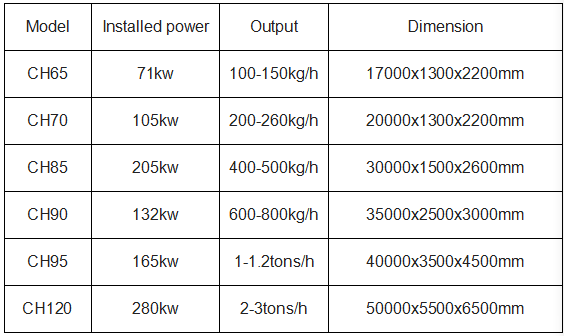

Product parameter

Select the model based on the production capacity.

Double screw extruder applications

Double screw extruders can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, turtle, bullfrog and other aquarium feed particles. Also can also make dog food

Fish feed extruder

Puffing technology refers to a certain moisture content of material is fed into extrusion machine, under the impetus of the screw, screw, material forming axial moving forward, material and screw, material to the mechanical friction within the barrel and material, the material being strong extrusion mixing, shearing, is further refined materials, homogenization, then machine the inside of the cavity pressure and temperature increasing and increases, Under the action of high temperature, high pressure and high shear force, the material components undergo complex physical and chemical changes. After the paste material is ejected from the die hole, the pressure difference is generated instantaneously, and the material is expanded, thus forming the expanded product with loose structure, porous and crisp. Twin-screw extruder fish feed production machinery aquatic feed production line quality is excellent

After puffing treatment, feed raw materials have a unique fragrance and fluffy feeling, good palatability, high gelatinization degree, and a good role in inducing food. At the same time, the long-chain structure of some organic matter such as protein and fat becomes short-chain structure, which makes it easier for animals to digest and absorb. The extruded feed grain size is small, crisp, and released char flavor, palatability is improved. The EXPANDED FEED BECOMES loose and disordered structure, and this change provides a larger contact area for enzymes, which is conducive to the contact of starch chain, peptide chain and digestive enzymes, and is conducive to the digestion and absorption of feed, so as to improve the digestibility of feed.

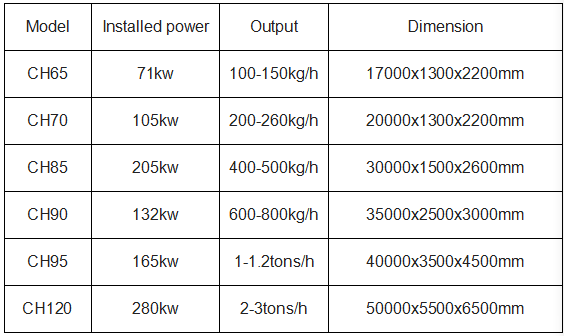

Product parameter

Select the model based on the production capacity.

Double screw extruder applications

Double screw extruders can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, turtle, bullfrog and other aquarium feed particles. Also can also make dog food

Fish feed extruder

Puffing technology refers to a certain moisture content of material is fed into extrusion machine, under the impetus of the screw, screw, material forming axial moving forward, material and screw, material to the mechanical friction within the barrel and material, the material being strong extrusion mixing, shearing, is further refined materials, homogenization, then machine the inside of the cavity pressure and temperature increasing and increases, Under the action of high temperature, high pressure and high shear force, the material components undergo complex physical and chemical changes. After the paste material is ejected from the die hole, the pressure difference is generated instantaneously, and the material is expanded, thus forming the expanded product with loose structure, porous and crisp. Twin-screw extruder fish feed production machinery aquatic feed production line quality is excellent

After puffing treatment, feed raw materials have a unique fragrance and fluffy feeling, good palatability, high gelatinization degree, and a good role in inducing food. At the same time, the long-chain structure of some organic matter such as protein and fat becomes short-chain structure, which makes it easier for animals to digest and absorb. The extruded feed grain size is small, crisp, and released char flavor, palatability is improved. The EXPANDED FEED BECOMES loose and disordered structure, and this change provides a larger contact area for enzymes, which is conducive to the contact of starch chain, peptide chain and digestive enzymes, and is conducive to the digestion and absorption of feed, so as to improve the digestibility of feed.

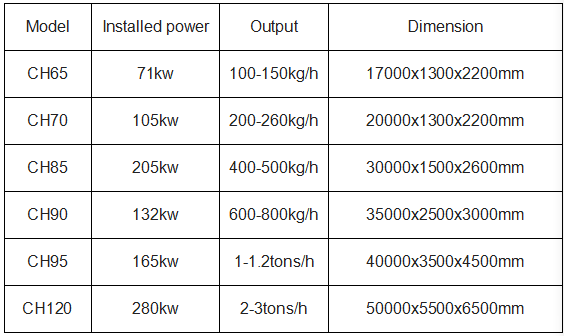

Product parameter

Select the model based on the production capacity.

Double screw extruder applications

Double screw extruders can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, turtle, bullfrog and other aquarium feed particles. Also can also make dog food

Fish feed extruder

Puffing technology refers to a certain moisture content of material is fed into extrusion machine, under the impetus of the screw, screw, material forming axial moving forward, material and screw, material to the mechanical friction within the barrel and material, the material being strong extrusion mixing, shearing, is further refined materials, homogenization, then machine the inside of the cavity pressure and temperature increasing and increases, Under the action of high temperature, high pressure and high shear force, the material components undergo complex physical and chemical changes. After the paste material is ejected from the die hole, the pressure difference is generated instantaneously, and the material is expanded, thus forming the expanded product with loose structure, porous and crisp. Twin-screw extruder fish feed production machinery aquatic feed production line quality is excellent

After puffing treatment, feed raw materials have a unique fragrance and fluffy feeling, good palatability, high gelatinization degree, and a good role in inducing food. At the same time, the long-chain structure of some organic matter such as protein and fat becomes short-chain structure, which makes it easier for animals to digest and absorb. The extruded feed grain size is small, crisp, and released char flavor, palatability is improved. The EXPANDED FEED BECOMES loose and disordered structure, and this change provides a larger contact area for enzymes, which is conducive to the contact of starch chain, peptide chain and digestive enzymes, and is conducive to the digestion and absorption of feed, so as to improve the digestibility of feed.

Product parameter

Select the model based on the production capacity.

Double screw extruder applications

Double screw extruders can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, turtle, bullfrog and other aquarium feed particles. Also can also make dog food

Fish feed extruder

Puffing technology refers to a certain moisture content of material is fed into extrusion machine, under the impetus of the screw, screw, material forming axial moving forward, material and screw, material to the mechanical friction within the barrel and material, the material being strong extrusion mixing, shearing, is further refined materials, homogenization, then machine the inside of the cavity pressure and temperature increasing and increases, Under the action of high temperature, high pressure and high shear force, the material components undergo complex physical and chemical changes. After the paste material is ejected from the die hole, the pressure difference is generated instantaneously, and the material is expanded, thus forming the expanded product with loose structure, porous and crisp. Twin-screw extruder fish feed production machinery aquatic feed production line quality is excellent

After puffing treatment, feed raw materials have a unique fragrance and fluffy feeling, good palatability, high gelatinization degree, and a good role in inducing food. At the same time, the long-chain structure of some organic matter such as protein and fat becomes short-chain structure, which makes it easier for animals to digest and absorb. The extruded feed grain size is small, crisp, and released char flavor, palatability is improved. The EXPANDED FEED BECOMES loose and disordered structure, and this change provides a larger contact area for enzymes, which is conducive to the contact of starch chain, peptide chain and digestive enzymes, and is conducive to the digestion and absorption of feed, so as to improve the digestibility of feed.

Product parameter

Select the model based on the production capacity.

Double screw extruder applications

Double screw extruders can produce and process catfish, grass carp, crucian carp, tilapia, ornamental fish, turtle, bullfrog and other aquarium feed particles. Also can also make dog food