Condition: New Place of Origin: Shandong China Brand Name: CH Machinery Model Number : CH-65,CH-70,CH-85 Output: 100-150kg/hour,200-240kg/h,300-400kg/h Voltage: Make based on customers’ factory voltage Dimension(L*W*H):20*1.5*2.2m Certification: CE, ISO9001 Warranty: 1year After-sales Service Provided: Field installation, commissioning and training Layout: Auto CAD format according to client's workshop

Fish feed aquatic feed production line

Since 1856, the United States Ward applied for the first patent on extrusion, many developed countries have made extensive research on extrusion related equipment and technology, extrusion technology in the industrial application is more and more favored.

The application of extrusion technology in the feed industry began in the United States in the 1950s. It is mainly used for processing pet feed, pretreating animal feed to improve digestibility and palatability, and producing urea feed as a protein supplement for ruminants. In the 1980s, extrusion technology has become a new feed processing technology with the fastest development rate abroad. It has incomparable advantages over traditional processing methods in processing special animal feed, aquatic feed, early weaned piglet feed and feed resource development.

How to make aquatic feed?

Need get the fish feed production line. The following picture is the whole line to make aquatic feed.

How does this line working?

Raw material grinding---mixing---feeding---cooking---drying---flavoring---packing

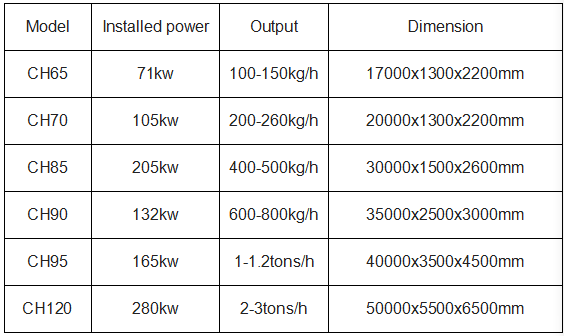

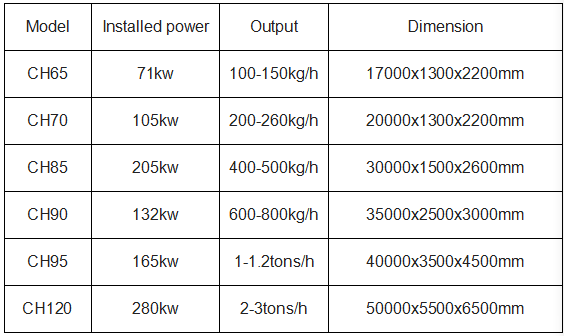

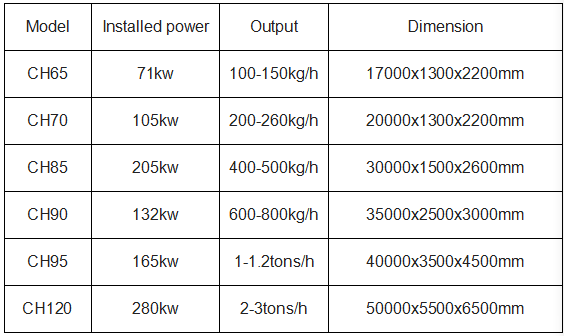

Product parameter

Select the model based on the production capacity.

Raw material intake

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

What other products can this production line produce?

Fish feed aquatic feed production line

Since 1856, the United States Ward applied for the first patent on extrusion, many developed countries have made extensive research on extrusion related equipment and technology, extrusion technology in the industrial application is more and more favored.

The application of extrusion technology in the feed industry began in the United States in the 1950s. It is mainly used for processing pet feed, pretreating animal feed to improve digestibility and palatability, and producing urea feed as a protein supplement for ruminants. In the 1980s, extrusion technology has become a new feed processing technology with the fastest development rate abroad. It has incomparable advantages over traditional processing methods in processing special animal feed, aquatic feed, early weaned piglet feed and feed resource development.

How to make aquatic feed?

Need get the fish feed production line. The following picture is the whole line to make aquatic feed.

How does this line working?

Raw material grinding---mixing---feeding---cooking---drying---flavoring---packing

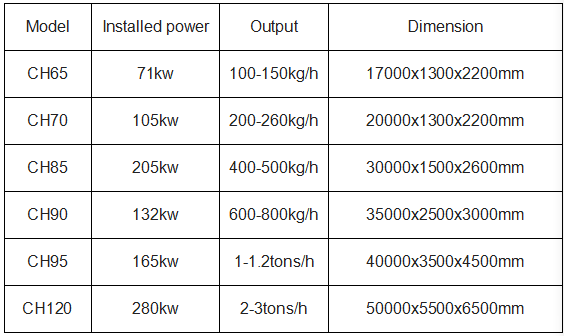

Product parameter

Select the model based on the production capacity.

Raw material intake

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

What other products can this production line produce?

Fish feed aquatic feed production line

Since 1856, the United States Ward applied for the first patent on extrusion, many developed countries have made extensive research on extrusion related equipment and technology, extrusion technology in the industrial application is more and more favored.

The application of extrusion technology in the feed industry began in the United States in the 1950s. It is mainly used for processing pet feed, pretreating animal feed to improve digestibility and palatability, and producing urea feed as a protein supplement for ruminants. In the 1980s, extrusion technology has become a new feed processing technology with the fastest development rate abroad. It has incomparable advantages over traditional processing methods in processing special animal feed, aquatic feed, early weaned piglet feed and feed resource development.

How to make aquatic feed?

Need get the fish feed production line. The following picture is the whole line to make aquatic feed.

How does this line working?

Raw material grinding---mixing---feeding---cooking---drying---flavoring---packing

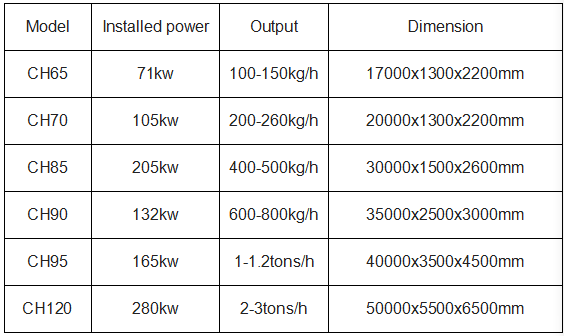

Product parameter

Select the model based on the production capacity.

Raw material intake

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

What other products can this production line produce?

Fish feed aquatic feed production line

Since 1856, the United States Ward applied for the first patent on extrusion, many developed countries have made extensive research on extrusion related equipment and technology, extrusion technology in the industrial application is more and more favored.

The application of extrusion technology in the feed industry began in the United States in the 1950s. It is mainly used for processing pet feed, pretreating animal feed to improve digestibility and palatability, and producing urea feed as a protein supplement for ruminants. In the 1980s, extrusion technology has become a new feed processing technology with the fastest development rate abroad. It has incomparable advantages over traditional processing methods in processing special animal feed, aquatic feed, early weaned piglet feed and feed resource development.

How to make aquatic feed?

Need get the fish feed production line. The following picture is the whole line to make aquatic feed.

How does this line working?

Raw material grinding---mixing---feeding---cooking---drying---flavoring---packing

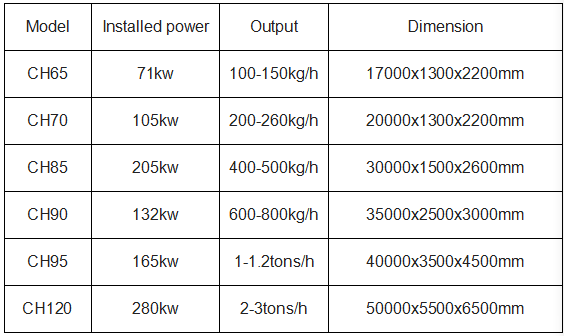

Product parameter

Select the model based on the production capacity.

Raw material intake

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

What other products can this production line produce?

Fish feed aquatic feed production line

Since 1856, the United States Ward applied for the first patent on extrusion, many developed countries have made extensive research on extrusion related equipment and technology, extrusion technology in the industrial application is more and more favored.

The application of extrusion technology in the feed industry began in the United States in the 1950s. It is mainly used for processing pet feed, pretreating animal feed to improve digestibility and palatability, and producing urea feed as a protein supplement for ruminants. In the 1980s, extrusion technology has become a new feed processing technology with the fastest development rate abroad. It has incomparable advantages over traditional processing methods in processing special animal feed, aquatic feed, early weaned piglet feed and feed resource development.

How to make aquatic feed?

Need get the fish feed production line. The following picture is the whole line to make aquatic feed.

How does this line working?

Raw material grinding---mixing---feeding---cooking---drying---flavoring---packing

Product parameter

Select the model based on the production capacity.

Raw material intake

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

What other products can this production line produce?

Fish feed aquatic feed production line

Since 1856, the United States Ward applied for the first patent on extrusion, many developed countries have made extensive research on extrusion related equipment and technology, extrusion technology in the industrial application is more and more favored.

The application of extrusion technology in the feed industry began in the United States in the 1950s. It is mainly used for processing pet feed, pretreating animal feed to improve digestibility and palatability, and producing urea feed as a protein supplement for ruminants. In the 1980s, extrusion technology has become a new feed processing technology with the fastest development rate abroad. It has incomparable advantages over traditional processing methods in processing special animal feed, aquatic feed, early weaned piglet feed and feed resource development.

How to make aquatic feed?

Need get the fish feed production line. The following picture is the whole line to make aquatic feed.

How does this line working?

Raw material grinding---mixing---feeding---cooking---drying---flavoring---packing

Product parameter

Select the model based on the production capacity.

Raw material intake

Rice flour, corn flour, wheat flour, low temperature soya flakes meal, rice bran , wheat bran, fish powder, bone powder etc.

What other products can this production line produce?